Applicator

Robot mounted bell:

At Acube Innotech, we understand that applicator selection is crucial in achieving the desired results while meeting specific conditions. That's why we offer a comprehensive range of advanced paint applicators to suit various requirements for industrial painting applications. With cutting-edge technology, we have utilized every form of applicator to ensure optimal performance on each component. Bell Applicators: Our Bell applicators represent the pinnacle of paint application technology, offering unmatched precision, speed, and consistency. With their robotic integration and advanced spraying capabilities, Bell applicators ensure uniform coverage and superior finish quality on a wide range of components.

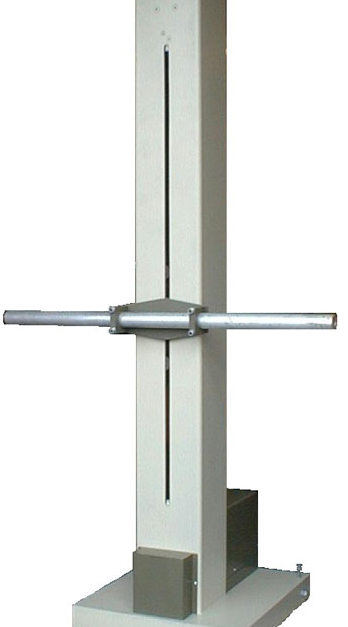

Machine Mounted Bell:

Introducing our Machine Mounted Bell Applicator – a compact and efficient solution designed to streamline your spray painting processes. Mounted directly onto your existing machinery, this innovative applicator delivers precise and uniform paint coverage for a variety of industrial applications. With seamless integration and advanced technology, our Machine Mounted Bell Applicator offers versatility, reliability, and enhanced productivity, ensuring superior finish quality while minimizing downtime.

Machine Mounted Auto Gun:

An innovative solution engineered to streamline your spray painting processes with unparalleled efficiency and precision. Designed to seamlessly integrate with your existing machinery, this advanced auto gun offers a versatile and reliable solution for a wide range of industrial painting applications. With its compact design and intuitive controls, our Machine Mounted Auto Gun provides ease of installation and operation, allowing you to achieve consistent and uniform paint coverage on various components. Whether you're painting metal parts, plastic products, or other materials, our auto gun delivers superior finish quality while maximizing productivity and minimizing waste.

Manual Spray Gun:

Manual Spray Gun – a versatile and user-friendly solution for your spray painting needs. Designed for ease of use and reliability, our manual spray gun is suitable for a wide range of industrial and commercial applications. With its ergonomic design and lightweight construction, it provides comfortable handling and precise control, allowing operators to achieve consistent paint coverage and superior finish quality. Whether you're painting small parts or large surfaces, our manual spray gun offers flexibility and versatility to meet your specific requirements. Our arsenal of paint Gun includes: Conventional Guns: Versatile and reliable, conventional guns are ideal for a wide range of painting tasks, offering flexibility and ease of use.

Air-Assisted Guns: Providing enhanced atomization and control, air-assisted guns deliver superior finish quality and coverage, particularly on complex surfaces. Electrostatic Guns: Harnessing the power of electrostatic technology, these guns offer efficient paint transfer and wraparound coverage, reducing overspray and improving transfer efficiency. Airless Guns: a powerful and efficient solution for precise paint application. With advanced technology and adjustable pressure settings, our spray gun provides uniform coverage on various surfaces without the need for compressed air. Ideal for coating large areas and hard-to-reach surfaces, it ensures professional results with ease.